West Coast IPA style using Weyermann malts.

Brew went smoothly;

- Mash in using the drill-bit paddle and regular mash paddle, a bit faster to mash in.

- Good volumes, slightly more grain (6.5kg) so mash volume 17L instead of the usual 16.5L.

- Brew jacket and heat dish make a noticeable difference in getting to the boil and keeping a nice consistent rolling boil.

- Used a hop basket for the first time – it is the smaller one designed for in-fermenter additions so it wasn’t ideal for the boil hops. A larger sized one would be better if at all.

- Drill-bit paddle was very effective at whirlpool to aerate the wort. Using it during the whirlpool periodically helped speed up the cooling substantially too.

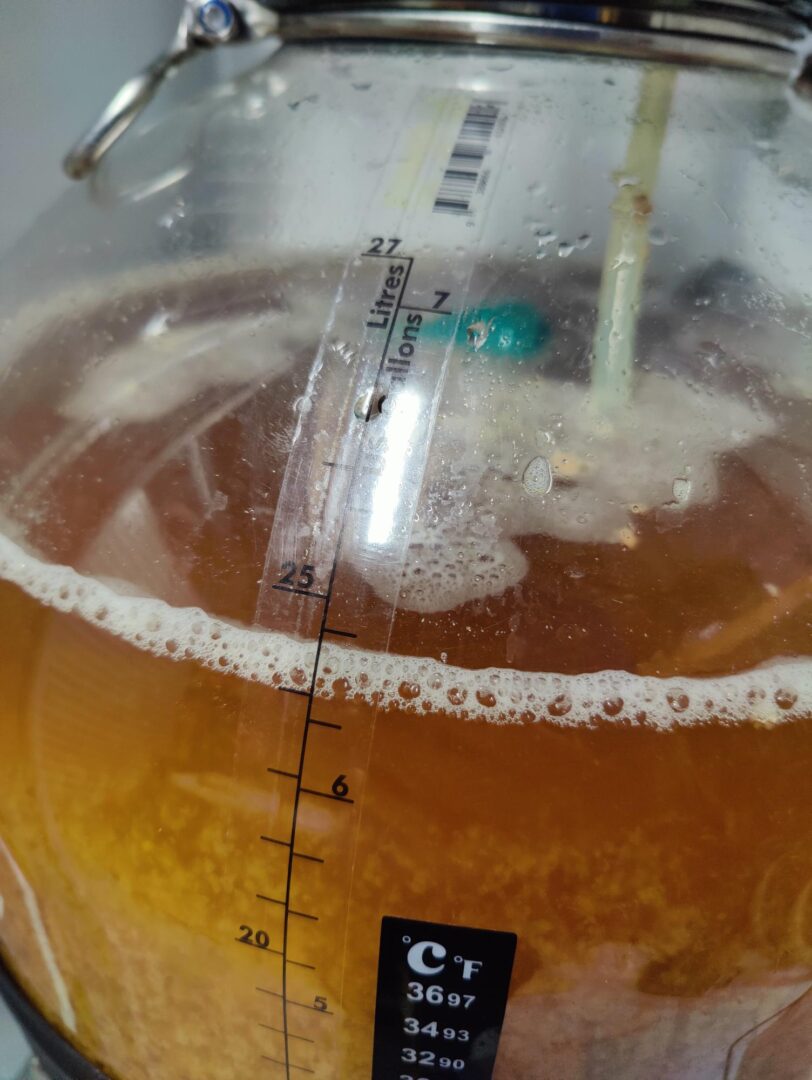

- 24L in fermenter, SG 1.061

Day 2:

Approx 48hours in, gravity 1.031 (-30pts 4% ish) fermentation going well.

Fermenting at 10psi to help keep it under control. I’ve had issues the past few brews with overflowing yeast foam. So far seems ok but it might ramp up still..

The BRY-97 is very neutral yeast so I’m not worried about suppressing esters at the higher pressure (usually ferment at around 4psi for an ipa/ale, and no pressure for abbaye).

Day 6 (Friday)

Morning: gravity at 1.010 and 7% abv. Only a couple points change over the last two days so it’s pretty well finished. Start the next phase with diacetyl rest, dry hop, trub dump etc…

Purged the jar with CO2 and checked seals. Issues with the connector posts again, they’ve developed small cracks. Used a little plumbing tape to help seal.

Opened the valve and dropped yeast into the jar. Since I used the mesh for boil / WP hops the jar is a clean beer/yeast with very little hops in it. Let it settle then closed the valve with the plan of extracting the yeast(?).

Added dry hop addition (50g each citra, superdelic, nectaron): released fermentation pressure from 10psi to 0, opened lid, added hops, sanitizer for good measure, closed lid, allowed a minute for any air that may have entered to float to the top of the gas in the head (it quickly rose to a few psi since there was a decent amount of CO2 in solution), purged to release head gas to ensure no air and only co2, closed spunding valve to begin CO2 capture and self carbonation.

Raised temperature from 18C to 20C for diacetyl rest.

Day 7:

Gravity 1.010, 7%. Pressure up to about 18psi

Day 8: Sunday

Gravity at 1.010, 7% abv. Temp still at 20C, pressure has come up to 22psi.

Removed the collection jar, it was stubborn and the thread cracked when I untightened it so I need a new jar. Side seals were a bit leaky now anyway.

I left a good amount of yeast in the jar and let it settle in the fridge. Poured off the beer at the top and replaced with cooled boiled water. Will do another wash or two to clean the yeast and keep it in the fridge.

Unsure about dextrose feeding / washing and portioning schedule so there’s a bit to learn..

Day 12 and 13:

Gravity still around 1.010 / 1.009 = 7%

Pressure has come up to 28 – 30 PSI

Started cooling initially to 12C then to 4C on Friday.

Day 15

Friday night tasting, ready to transfer into the all rounder.

Saturday morning transferred to the all rounder with liquid finings.

Bottled what was left in fermenter to make space for the next brew – approx 13.5L