West Coast RIPA notes

This West Coast RIPA is my next iteration of a red IPA brew – check out other red IPA brews to see how they compare.

It uses a good amount of Vienna to balance the aurora/shepherds delight/rye on an American Ale base.

A hefty amount of hops for a 23L brew at 330g total, almost even split of mosaic and riwaka.

Brew went smoothly / well – good volumes and reasonably high initial gravity.

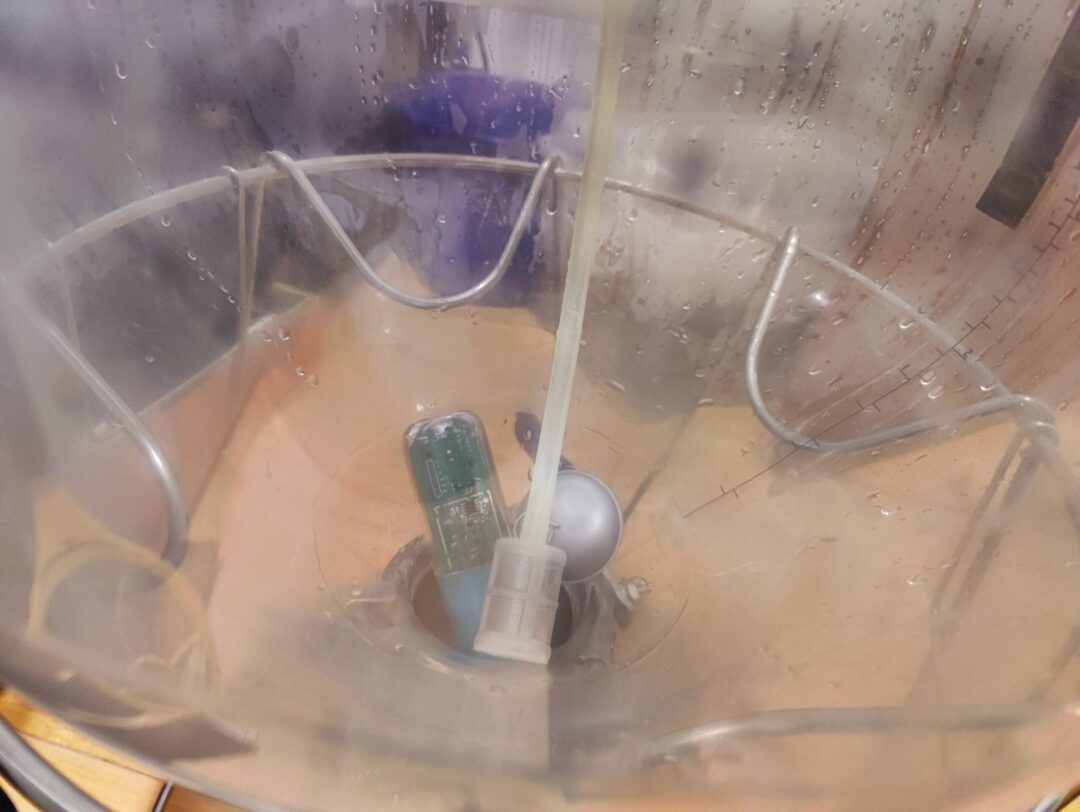

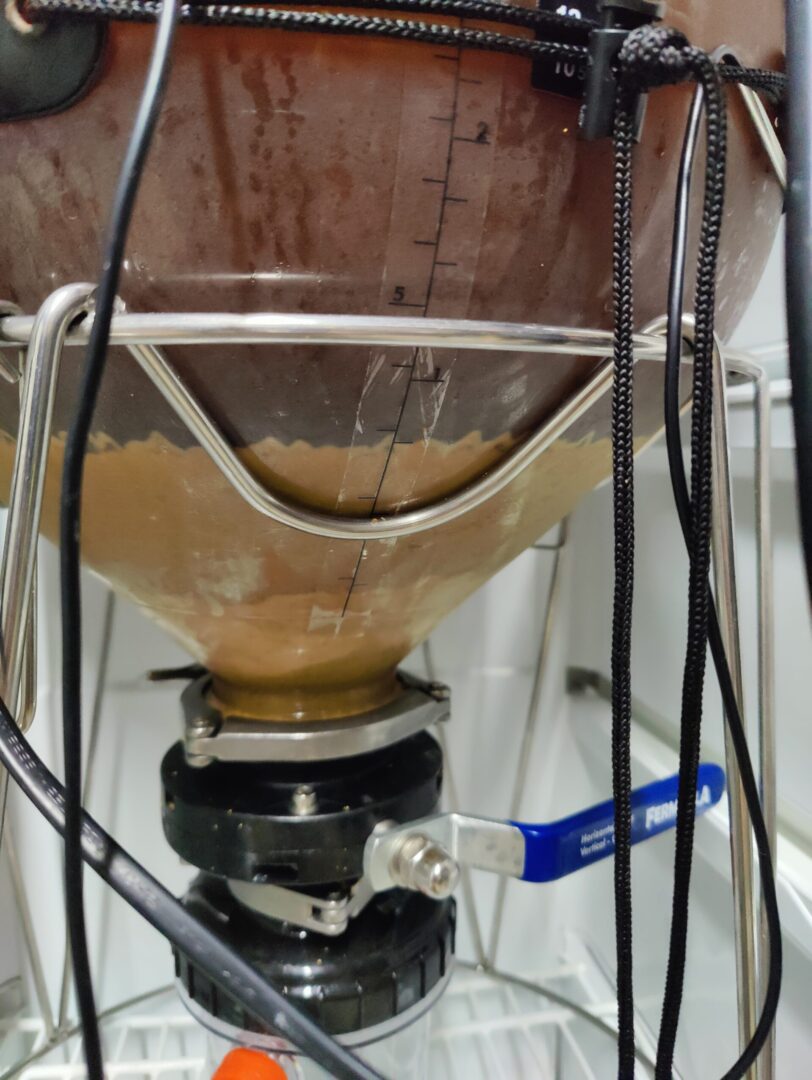

I used the conical fermenter with trub collector for this brew – now that I have CO2 gas bottle I can purge the collector and dump the trub to help with clarification. This step also meant I did not worry about whirlpool and settling the hops into a filter bed before transfer, instead just transferred quickly and stirred to prevent the hop-bed blocking the flow. I can easily remove this using the fermenter collector etc later.

Day 1

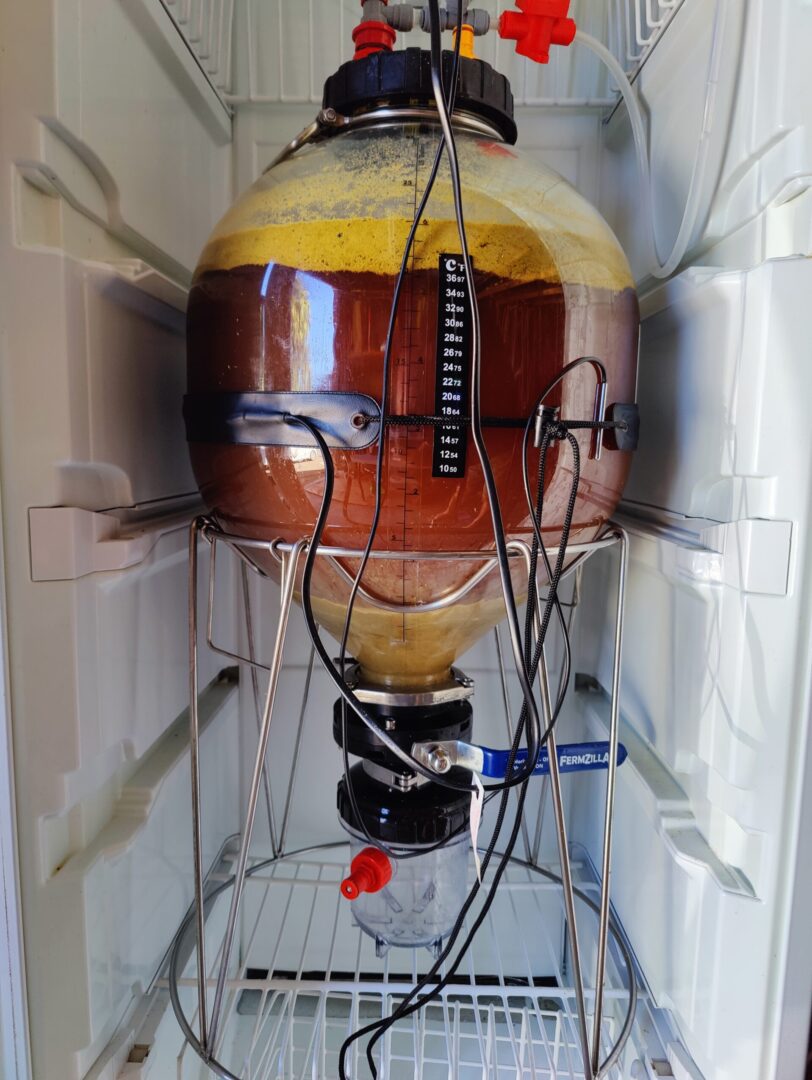

Day 3

Very high krausen / foam – some starting to hit the top of the fermenter. 26L likely a bit high, 18C should’ve slowed the fermentation compared to 20C (like last brew).

Day 4

Cleared the spunding valve and bubbler line – a little yeast foam made its way through. Pressure around 4PSI, SG at 1.016 for most of the day, likely on the tail end of fermentation, estimate a point or two left to change. ABV at approx. 6.5%.

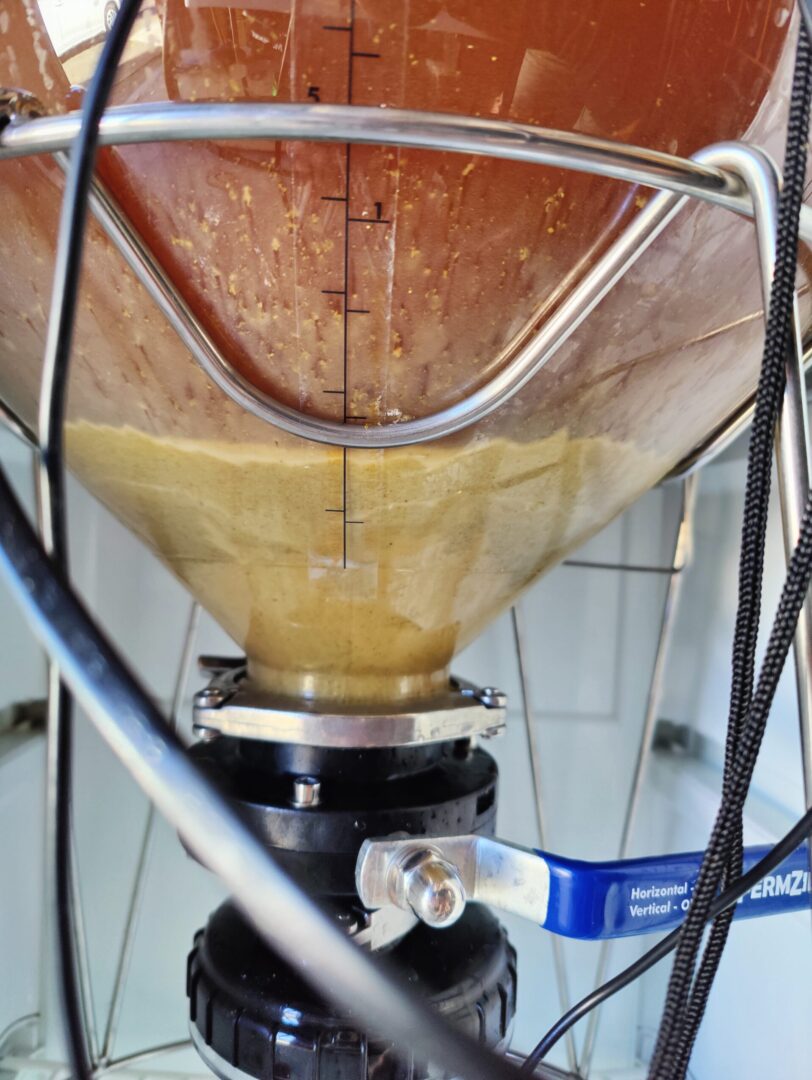

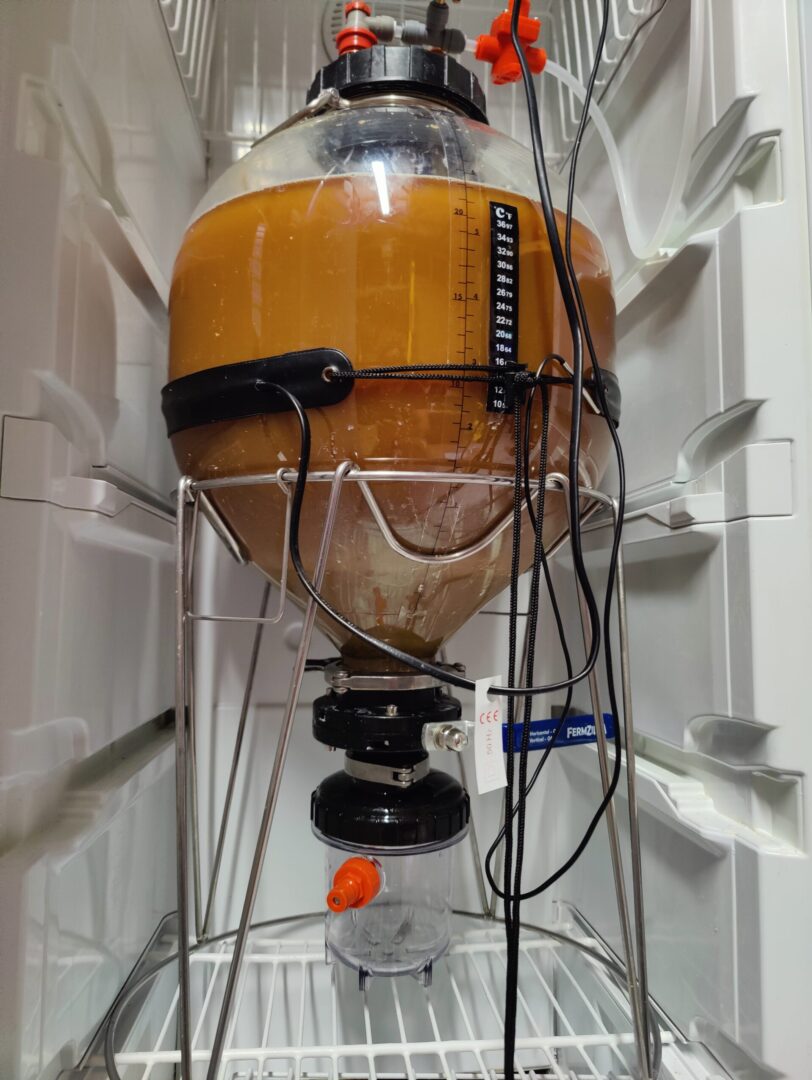

Day 5 – West Coast RIPA trub dump and dry hop

Dumped the trub. I connected the CO2 bottle to the bottom jar via the red connector post, checked/troubleshooted seal/leaks and then purged the jar. Opened the valve and let the trub fall through. Emptied the jar and repeated a second time.

Sanitised, sealed and purged the jar, then dry hopped through the top as usual.

SG was 1.015 before the trub/dry hopping, and a few hours later down to 1.011.

I purged the fermenter to release any air that entered during the dry hop addition, then closed the spunding valve. Pressure came up to about 12psi in the evening.

Day 7

Hops settled down after initially floating. Gravity at 1.014 (up from the 1.010 after being disturbed by hops floating on the top).

Pressure at 22psi (at 18C) after 2days of capture.

Increased temperature to 20C.

Day 8

Temperature at 20C.

Pressure increased to 26psi.

Given enough time this would give 2.34 volumes of CO2.

SG 1.013.

Day 9

Pressure had increased to 27.4, so I opened the spunding valve slightly to decrease and hold it at about 26psi.

gravity still at 1.013.

Day 10

Rest phase completed at 20C for a couple of days.

Purged and checked seals of bottom jar – very slight leaks where some cracks have formed at the pet lid connector posts.

Opened the bottom valve and let the sediment settle a little before closing the valve and emptying the jar.

Sanitised and resealed the jar on the bottom of the fermenter.

Pressure reset to 26psi.

Gravity moved around during this process but has returned to around 1.013 to 1.014.

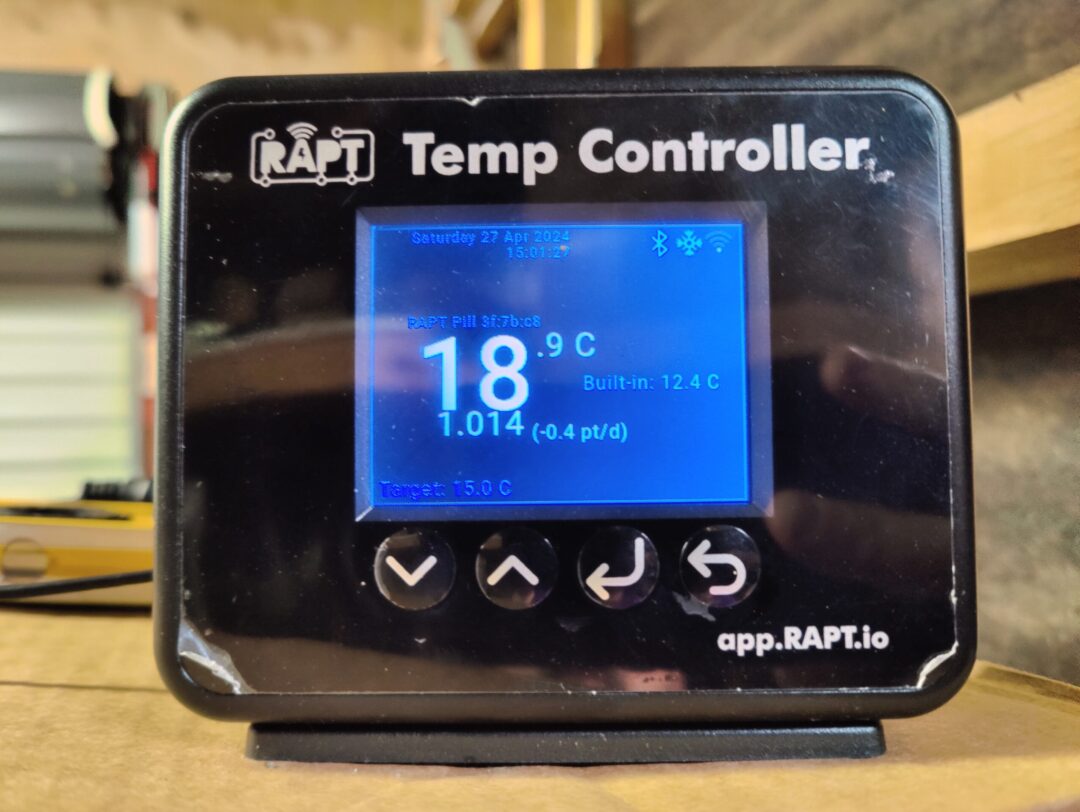

Decreased target temperature to 15C.

Day 11

lowered temp to 12C (AM) – pressure 20.4PSI

lowered temp to 9C (PM afternoon) – pressure 18.7PSI

lowered temp to 6C (PM evening)

Day 12

AM

set target temperature to 3C.

Pressure was 14.9psi

PM

connected counter pressure filler to pull a sample without adjusting pressure.

There was a decent level of carbonation (self carbonated).

Not particularly red, very drinkable.

A slight ‘fresh’ aftertaste, not dominant. I’ve noticed this particular flavour when sampling my beers at bottling, but then it’s gone after a week or two in the bottle.

Day 13 – bottling the West Coast RIPA

FG 1.012

ABV 7%

Bottled using counter pressure filler, getting the hang of it. There is a knack to the sprung pin release mechanism – it needs to be seated just right to allow a slow fill and no foam. Giving it a pull and jiggle when purging and pressurising allows a test to see how quickly the gas is releasing (and therefore fill speed). If pressure is too high the slowest setting is still too fast. Around 10psi allows a nice slow fill with now foam and good speed control.

Total volume bottled is 19.25L.