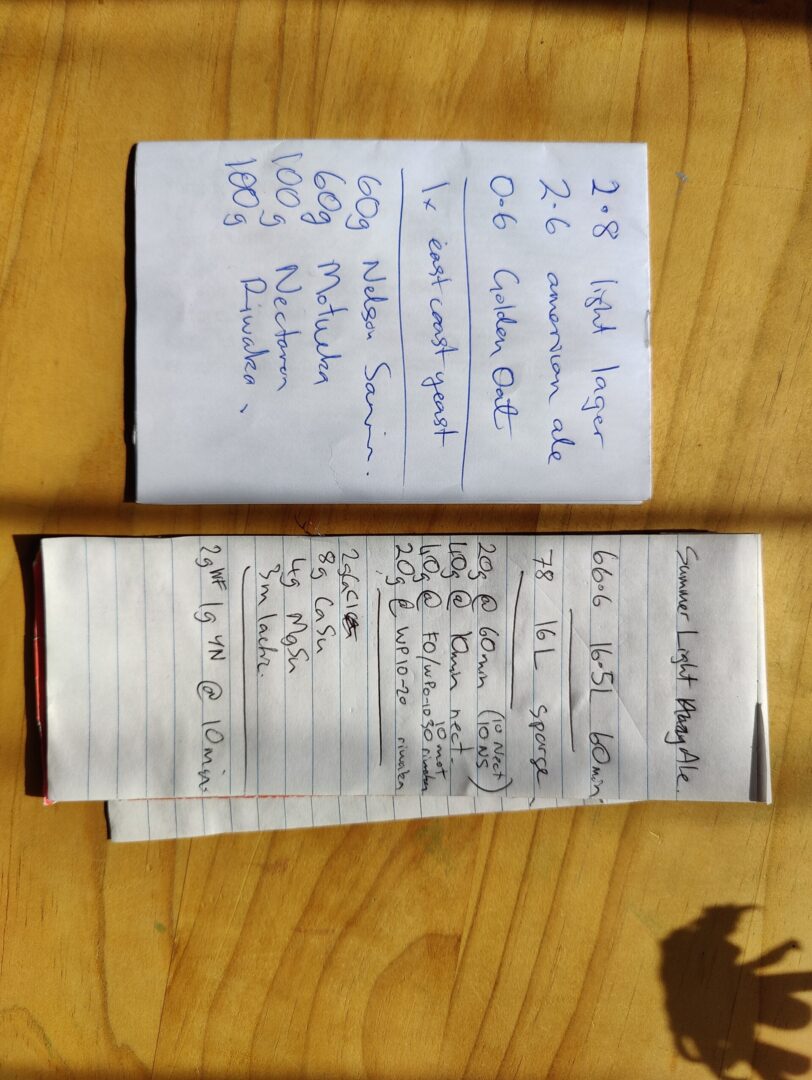

Light lager malt and american ale malt as a base, using Gladfield golden oat as specialty grain. Golden oat uses the big o to start with and treats it in the way as crystal malt (allow longer malting to fully covert sugars in the malt, leaving no enzymes, then roasting it to give a light golden caramel colour). First time using oat as specialty. Paired the grain base with the American East Coast yeast (1x packet) and a reasonably large hop bill – 120g total in the boil, 200g total for dry hop.

I’ve setup the float in the fermenter and bought the rest of the kit to allow pressure dispensing/bottling – this beer will be my first attempt at fully carbonating in the fermenter.

Ferment at 20C at 4psi, dry hop day 4, capture and build pressure from there. Raise to 22C around day 7.

Crash cool to as close to 0C 24hours before bottling

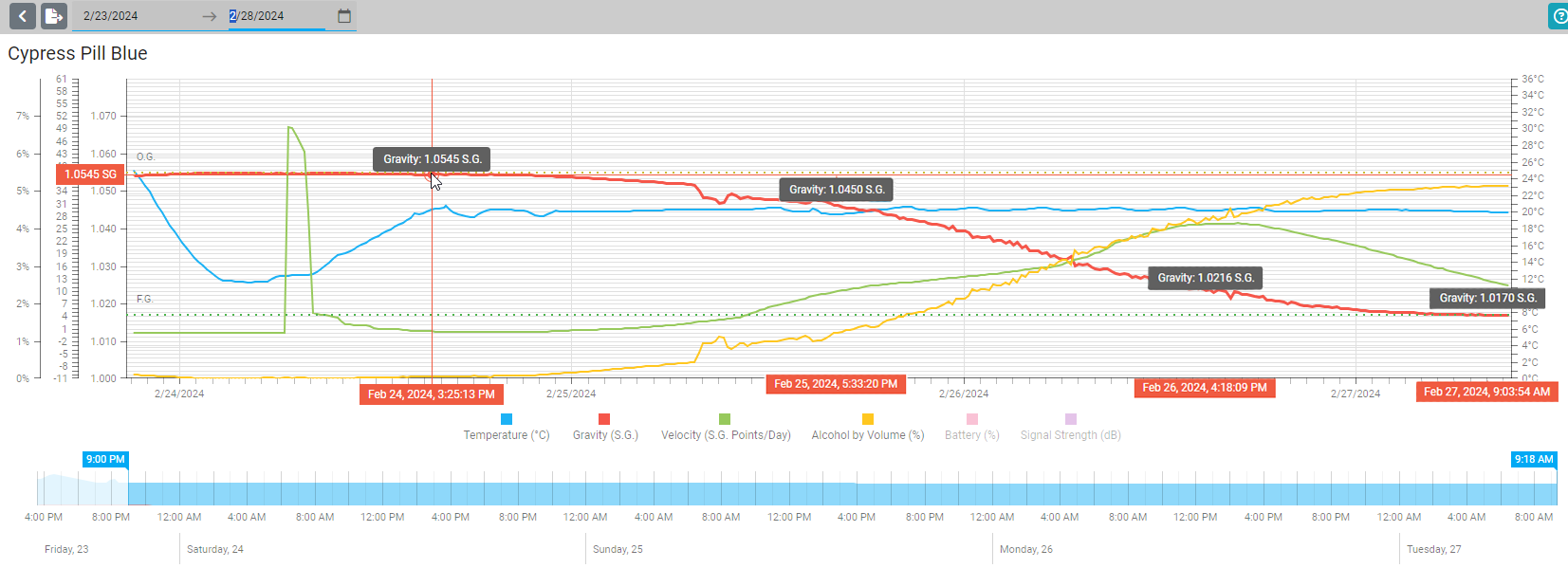

Forgot to adjust temp controller target and it was set at 12C previously – so the first 12 hours temperature came down from pitching (22C) to 12C. The next morning raised it to 20C. I don’t think this mattered, if anything just delayed the fermentation.

Fermentation took off as usual (a bit delayed) and pressure up and set to 4PSI.

once it’d reached 20C, gravity changed approx 10pts in 24hours, then approx 14pts the next 24hours. At 1.017 morning of day 4, abv 5%.

dry hopped day 4, riwaka, motueka, Nectaron, nelson Sauvin, total 200g (50g each)

I closed spunding valve and within a few hours pressure went up to nearly 15psi.

adjusted spunding to hold just under 15psi

Overnight gravity dropped to 1.012.

day 8 rasied temp 21, day 9 raised temp 21.5, day 10 rasied temp 22

gravity moved around a bit – possibly related to the hop stuff floating on the surface

seemed to settle to 1.012 @ 22C

day 12

lowered temp to 1C

pressure @ 22C = 1bar (approx 14psi)

pressure @ 1C = 9 psi

added gas line to increase pressure to 15psi

tested nukatap counter pressure filling tool. Works surprisingly well with the inline gas valve as a tap.

filled a bottle to test – very straight forward and very little foam while under pressure.

beer at 1C and 9psi was quite flat. Very tasty and a lot of aroma.

Left the gas line hooked up at 15psi and 1C to carbonate.

gravity at 1C is 1.010

bottled Saturday 12pm, day 15. Seemed carbonated enough. Getting the hang of the process, a few foamed up especially if the pressure changed on the outlet valve on the side of the filler. Managed to get about 17L bottled, after sampling the other few liters during the final few days to check carbonation.

Total 21L final in bottles 17L.

Very tasty, sampling one after bottling had a particular taste i’ve noticed at bottling – likely related to it needing time to condition, but wondering if it is related to the sanitizer.